Longitudinal Rip Mechanism

Longitudinal steel ropes inside conveyor belting increase tensile strength

and hinder transverse fracture. However, longitudinal strength of the

conveyor is not improved and longitudinal rip occurs frequently. The main

causes of longitudinal rip are as follows:

1. Rip Caused by Belt Deviation

When a large belt deviation occurs on one side of the conveyor, folding and

wrinkling will be formed on that side. The conveyor belt will be ripped

because of uneven tension.

2. Rip Caused by Material Blocking

Such a rip generally on the bottom of the chute in the following conditions:

limited clearance between the front of the chute and the conveyor belt,

uneven distribution forces exerted on the impact roller below the conveyor

belt, large sharp materials lodged between conveyor belt and chute.

3. Rip Caused by Puncture from Foreign Object

If a large foreign object becomes lodged between the head and tail of linked

conveyors, a puncture can occur.

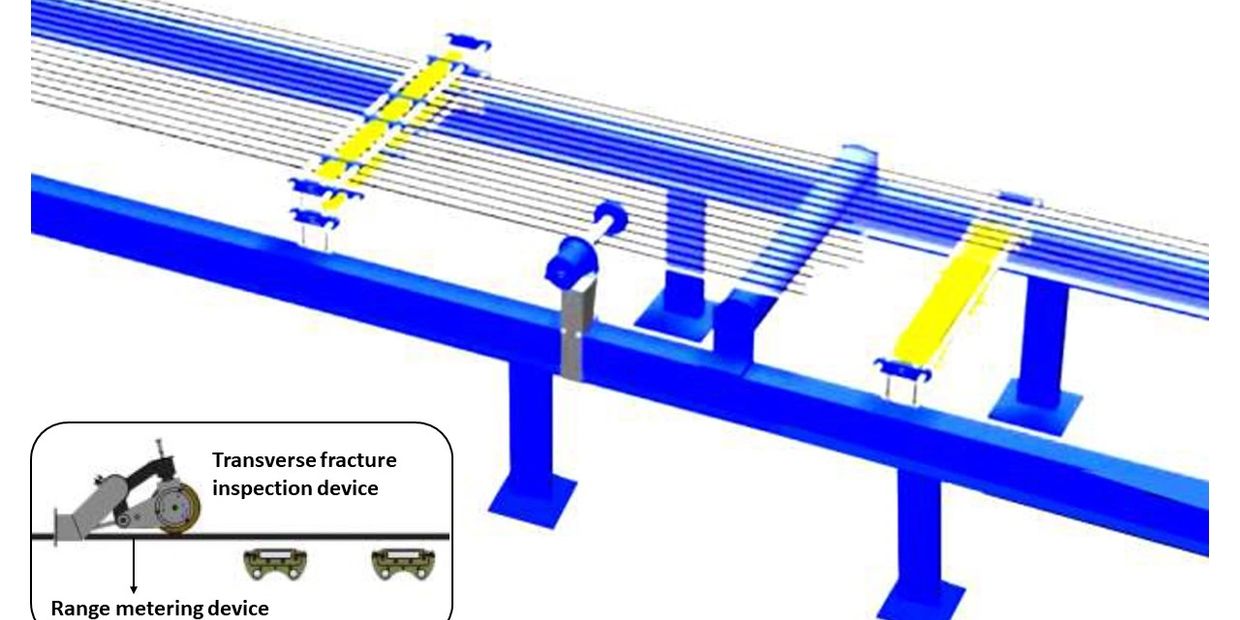

Longitudinal Rip Monitoring Device

Transverse Fracture Mechanism

Fracture generally occurs at the splice-joint. The belt splice is the weakest part with the lowest tensile strength. There are numerous causes for joint fracture: Insufficient coating, incorrect pressing temperature or pressure, core rust at the belt ends, and severe cuts in the belt. Regardless of which mechanism, deformation at the splice zone will increase and displacement of the steel rope core will occur. As time passes, the number of steel cores with local displacement will increase, resulting in plastic deformation at the splice zone. This will affect the bonding layer between the steel rope core and the rubber. When work load forces exceed the bonding forces, the steel rope will become exposed and result in fracture.

Transverse Fracture Inspection Device

Technical Principle and Method

Magnetic memory characteristics of ferro-magnetic materials are fully used

In the organization structure of ferro-magnetic materials, a kind of matter, magnetic domain, is arranged densely. Each magnetic domain is provided with one direction of spinning magnetic moment. If magnetic domain in some direction has advantages in quantity, materials will be magnetic at a macro level. If direction of spinning magnetic moment is unordered in magnetic domain, there will be no magnetic performance.

Magnetic memory inspection method is invented for the first time

In natural state, direction of spinning magnetic moment is unordered in the magnetic domain of steel rope. If an external field is applied to the steel rope, the number of magnetic domains in some direction of ferro-magnetic materials will be changed, bringing an appropriate low-magnitude magnetic energy product to all loading materials and thus forming a "memoryfield".

New technology of weak magnetic sensor is invented for the first time

Belt Scan's weak magnetic sensor, based on the innovative principle of "spatial field vector synthesis", gives weak electromagnetic field modulation & demodulation and forms association with magnetic memory information. Through extraction of memory information of ferro-magnetic materials with applied magnetic load, quantitative identification is completed for various defects of tested steel rope.